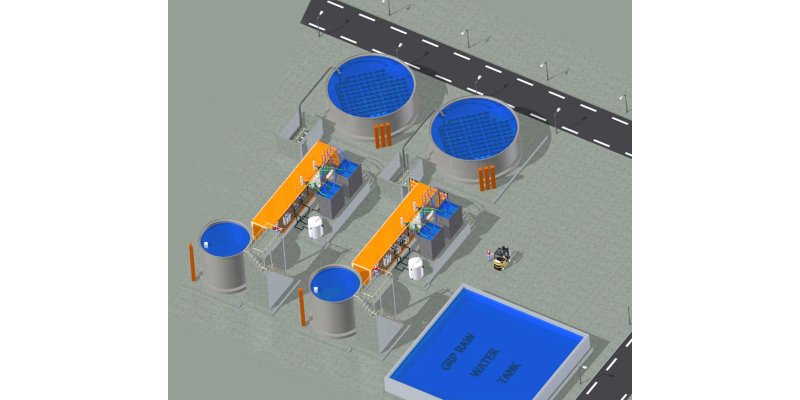

AQUALINE MEMBRANE BIOREACTORS Membrane Bioreactors are biological treatment plants which combines activated sludge process with submersed membrane filtration. Secondary settling tanks are replaced with membrane units. Complete solids removal, a significant bacteria removal capability, high rate and high efficiency organic removal and small footprint are the advantages of the MBR Systems.

The MBR process can be configured in many different ways depending on project specific nutrient removal objectives. Anoxic zones before or after the aerobic treatment may be used for denitrification, depending on the effluent nitrate and total nitrogen requirements. ESLI prefer submerged configuration because of less energy requirement and low fouling potential. In submerged configuration, a suction force is applied to draw the water through the membrane, while the sludge is retained on the membrane surface.

Membrane modules consist of hollow fiber bundles which are made of Polyvinylidene Flouoride (PVDF). Aeration nozzles are located in the centre of the fibre bundle to scour the entire fiber length, minimizing power consumption. Single header design reduces energy, minimizes downtime, and increases the flux, all within a small footprint. MBR treatment plants can be applied to wide capacity range. ESLI provides pre – engineered systems up to 1000 m3/day.

APPLICATION AREAS

Human-Induced (Urban) Wastewater,

Educational institutions and health service applications,

Hotels, labor and refugee camps, parks and military bases,

Construction complexes (workplaces, shopping malls, small shops),

Industrial wastewater, food and beverage industries etc.

AQUALINE MBR SYSTEMS

Turnkey MBR system

Standard, pre-designed package systems

Low area requirement for plant thanks to efficient compact design

Durable, high quality system and parts

Easy capacity increase

System product Water values that provide discharge standards or are much lower

ADVANTAGES OF MBR SYSTEMS

No need to apply final settling tank and tertiary filtration steps, this reduces the need for area for the facility.

Unlike final sedimentation tanks, the quality of solid matter treatment is independent of the suspended solids concentration and quality in the system.

Suitable for remote control as good sludge slump feature is not expected in the system.

With high sludge retention time, the amount of mud formed is lower as the design is made. It is suitable for re-use applications as UF quality product is obtained. It can be used as Reverse Osmosis feed water to obtain higher quality water.

AQUALINE MEMBRANE BIOREACTORS Membrane Bioreactors are biological treatment plants which combines activated sludge process with submersed membrane filtration. Secondary settling tanks are replaced with membrane units. Complete solids removal, a significant bacteria removal capability, high rate and high efficiency organic removal and small footprint are the advantages of the MBR Systems.