The design driver is fitting the most plate surfaces, at the most effective angle into the smallest per square foot space. This design allows the "settling area" or surface area to be as much as 10 times more than the actual floor space occupied by the clarifier. A significant reduction of the required floor space is achieved by reducing separation between plates to a few inches, and stacking the settling surfaces.

PRODUCT FEATURES

Based on physical and chemical treatment

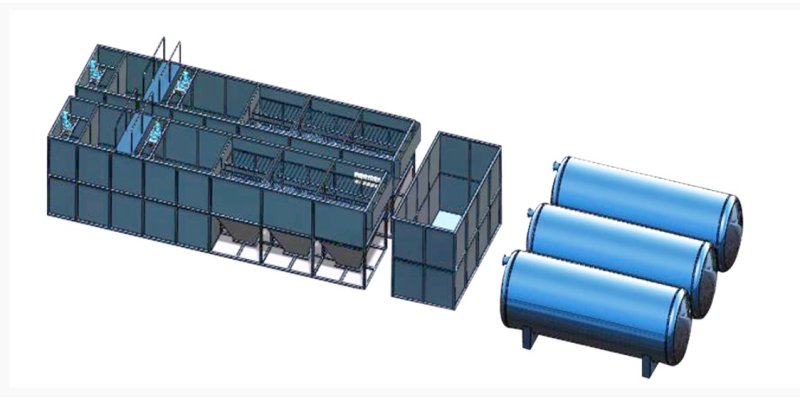

Two standard systems having capacity of 50 m3/h and 100 m3/h; for higher capacities, custom designs are made with using multi-systems.

10 times the equivalent settling area of traditional clarifiers

Corrosion-resistant and completely submerged PVC plates

Plates installed at 55 degree for optimal solids settling

Self-cleaning plates and no moving parts translate to low maintenance costs

Space-saving footprint allows for efficient use of land

APPLICATIONS

These compact treatment systems, which includes pre-chlorination, coagulation-flocculation, lamella clarification, sand filtration and post-chlorination, can be used ideally in which require separation of suspended solids, leaving effluent clear for discharge.

The raw water will be collected from Iraqi rivers or other freshwater aquatic ecosystems, in order to produce potable water for several domestic purposes. (human consumption and other common uses).

The treatment line of this water treatment plant includes:

1. PRE-CHLORINATION

The aim of flocculation-coagulation process is to remove the very thin particles, called colloids that are very important water constituents. They cause turbulence and a lot of times form stable colloidal suspensions

2. COAGULATION-FLOCCULATION

The aim of flocculation-coagulation process is to remove the very thin particles,

called colloids that are very important water constituents. They cause turbulence and a lot of times form stable colloidal suspensions

3. LAMELLA CLARIFICATION

The clarification of the raw water after chemical treatment is usually carried out by gravity sedimentation. In order to reduce the required sedimentation surface, it is very common to use lamellar sedimentation. Effectively, in contrast to conventional sedimentation, lamella sedimentation offers a high sedimentation surface when available terrain surface is reduced. After sedimentation, the treated water passes to a storage tank (regulation tank), from which the water is pumped using horizontal centrifugal pumps to pressure sand filters.

4. SAND FILTRATION

The main purpose of the sand filtration is to remove all small particles and flocks that have not been removed in clarification process, in order to obtain clear water ready for public supply.

5. DISINFECTION (POST-CHLORINATION)

In order to ensure the final quality of the treated water, post-chlorination is necessary operation;

specially regarding to required residual free chlorine levels.

The design driver is fitting the most plate surfaces, at the most effective angle into the smallest per square foot space. This design allows the "settling area" or surface area to be as much as 10 times more than the actual floor space occupied by the clarifier. A significant reduction of the required floor space is achieved by reducing separation between plates to a few inches, and stacking the settling surfaces.