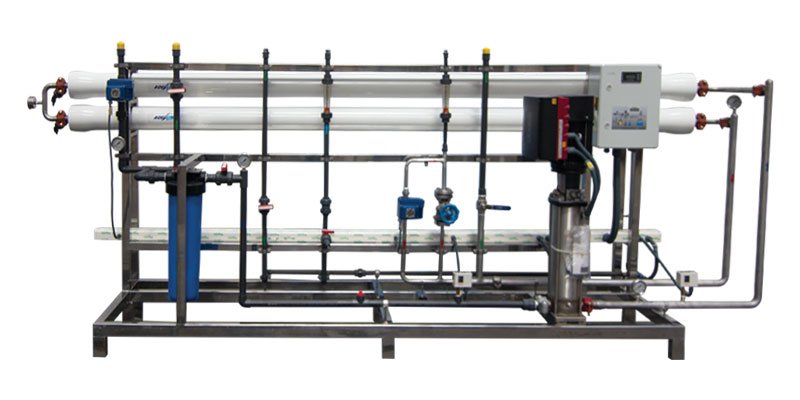

REVERSE OSMOSIS SYSTEMS / ALFA SERIES REVERSE OSMOSIS SYSTEMS

AQUALINE ALFA SERIES REVERSE OSMOSIS SYSTEMS

1 m3/day to 30 m3/day

Reverse Osmosis is the membrane filtration process for obtaining pure water, which separates all unwanted minerals from water, applied to waters where conventional treatment systems are insufficient (seawater, water with high conductivity, well waters, etc.). This process continues until osmotic equilibrium is achieved. Reverse osmosis is the reversal of this osmotic flow. Aqualine reverse Osmosis Systems successfully ensures that pure water is obtained as a result of this process. In addition, Aqualine Reverse Osmosis Systems can be produced in different design styles according to customer requests.

STANDARD FEATURES

Membrane vessels FRP or Stainless Steel

TFC spiral wound membranes 2,5’’ or 4’’ diameter

SS304 stainless steel vertical centrifuge high pressure pump (available in between ALFA 340/440/540/640)

Brass body rotary type high pressure pump (available in between ALFA125/140/240)

SS304 stainless steel frame

5 micron cartridge filter

Low and high pressure pipings U-PVC / Zonder PN20

Inlet solenoid valve

Pressure adjustment valves in Pump outlet and waste water line

Low and high pressure switches

Product water and waste water flowmeters

Reverse cycle flowmeters (Only available in Alfa 340/440/540/640)

Gliserin Filled Manometers

Product Water Conductivity Meter (0-2000µS/cm)

Autoflush System

On-Off switch

RO Electronic Control Card, Alarm and Position Indicators

220 V/50Hz/1ph ( between ALFA 125/140/240)

380 V/50Hz/3ph ( between ALFA 340/440/540/640)

IP56 Control Panel

INLET WATER LIMITS

Inlet water TDS: 0 - 2,000 ppm

Inlet water pressure: 2 to 5 bar

Inlet water pH range: 6-8

Silica (SiO2) Tolerance: Maximum 25 ppm

Minimum and maximum inlet water temperature (10ºC - 30ºC)

Maximum Iron (Fe) tolerance: 0.05 ppm, if ASC is dosed 0.2 ppm

Hydrogen Sulfide should not be.

There should be no turbidity (NTU <1)

No oil or grease

SDI <5

There should be no microbiological pollution